Hygienic process Management

How do you optimize your sanitary process and increase productivity?

Hygienic process management

Consumer expectations change daily. Like us, they take to heart preserving the environment and they are sensitive to product quality. We have been working side by side with our industrial partners for over 50 years in order to satisfy and guarantee the safety of all. More than ever, performance is thought out respecting regulations and optimizing production costs.That is why we accompany each customer by adapting, innovating and offering personalized solutions to their needs.

BACTERIOLOGY

Zero bacteriological risk

Consumer health is fundamental for each of us. For this reason, regulations are becoming more stringent. To guarantee your process safety ourt teams put their skills and know how at your service. Our equipment is also adapted to and certified compatible with your products – including the most fragile and demanding.

Our valves and seals have been designed to insure customer peace of mind in terms of cleanability, hygiene and compatibility with your products and processes.

Wait no longer : Choose the process valves most adapted to your needs.

How do you master biological risk?

- Secure the processes

- Choose a valve with no retention zones

- Respect regulations

- Hygienic and food safety certifications

- Assurer cleanability.

extreme conditions

High pressure and product aggressivity

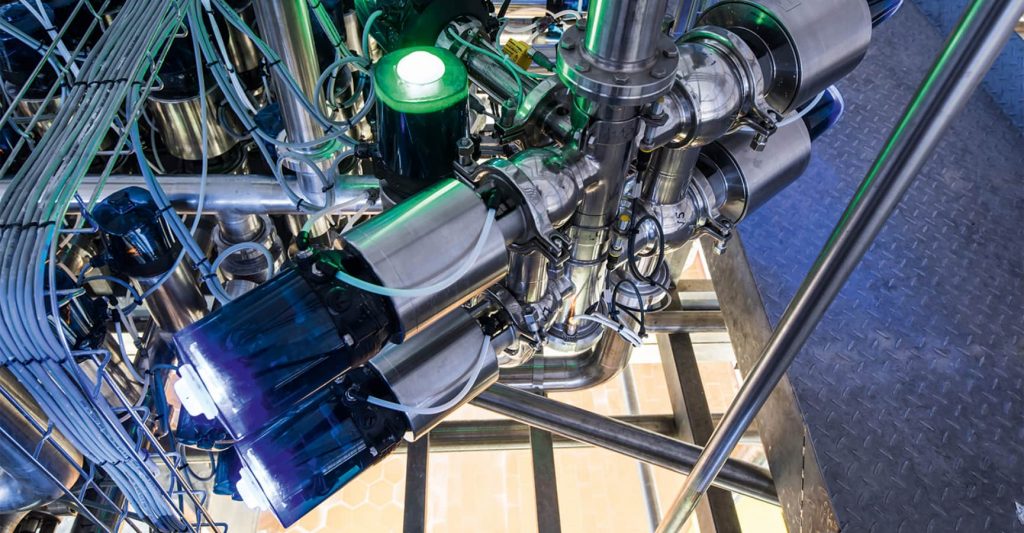

In a changing world, our ability to adapt is a condition to our performance. Every day, Definox valves and seals allow you to produce in complete safety under extreme conditions.

Faced with the aggressivity of certain products, their thermic and mechanical constraints, the equipment and material proposed must vary in order to maintain a high-performance level.

The properties of some products call for using specific materials: Hastelloy, Uranus B6, 904L, 254 SMO, AL6XN in place of…316L. For sealing materials for example, we use the latest generation elastomers EPDM, FKM, HNBR, or PFA, PTFE or PEEK. Discover our range of related products.

How do you manage the aggressivity of a product and high pressure?

- Choose specific watertight elastomers

- Choose heat resistant seals

- Specifically adapted materials

utilization rate

Boost your productivity with the “pigging system” and our high-tech process valves.

Producing better: one of the issues for tomorrow’s industries. The optimization of maintenance time is moving towards quantitative and qualitative performance. For all your products Definox proposes equipment that is performant and adapted. Thanks to their ingenious designs, our valves reduce and space out maintenance times. Their 100% cleanable design secures your productivity and guarantees a high bacteriological control. When it comes to high value products, scaping solutions are essential. The scraping system STARMOTION allows you to increase production reduce loss and optimize cleaning cycles. Our customers reduce waste and increase their production line utilization rates thanks to our scraping system. What about you?

How do you optimize the utilization rate of your production lines?

With the Pigging system STARMOTION, maintenance times are reduced, and cleaning plans NEP are adapted.

PRODUCT INTEGRITY

At Definox we know that product quality determines consumer satisfaction. That’s why the specific properties of your products are understood and respected: viscosity, particle size, fragility…our specialized process valves and seals ensure the continuous quality of the product: texture, entirety and fluidity. Our personalized scraping solutions allow for a passage that respects the product with the least obstacles possible. Product integrity is always optimal thanks to adapting the finishing level: surface state, small or large deflections, variable openings, plug retraction capacity. Are you looking for solutions more respectful of your products? Choose our products.

How do you guarantee product integrity?

A respectful passage adapts to specific properties (viscosity,size,fragility). The absence of obstacles, level of finishing and deflection are essential.

Modularity

Customizing : Our expertise from the beginning.

Providing solutions is the guarantee of a successful sustainable collaboration. More than just a supplier, Definox wants to be your partner of choice. Our range offers numerous possibilities for customization. Its richness and modularity are proof of our agility and dynamism.

Would you like to go further? Thanks to our expertise and our listening ability we accompany you in designing and realizing your personalized solutions and follow the development of the process together with the workshop, our prototype makers and engineers…

Adopt the configuration that suits your needs and discover your solution for tomorrow.

A Definox expertise

Customizing is an expertise that allow you to adapt the configuration of a color and add functions. Modularity allows for a longer product life.